-

China, Foshan City, Guangdong

-

Consult+86-15220990227

-

Mon - Sat: 8:00AM - 6:00PM

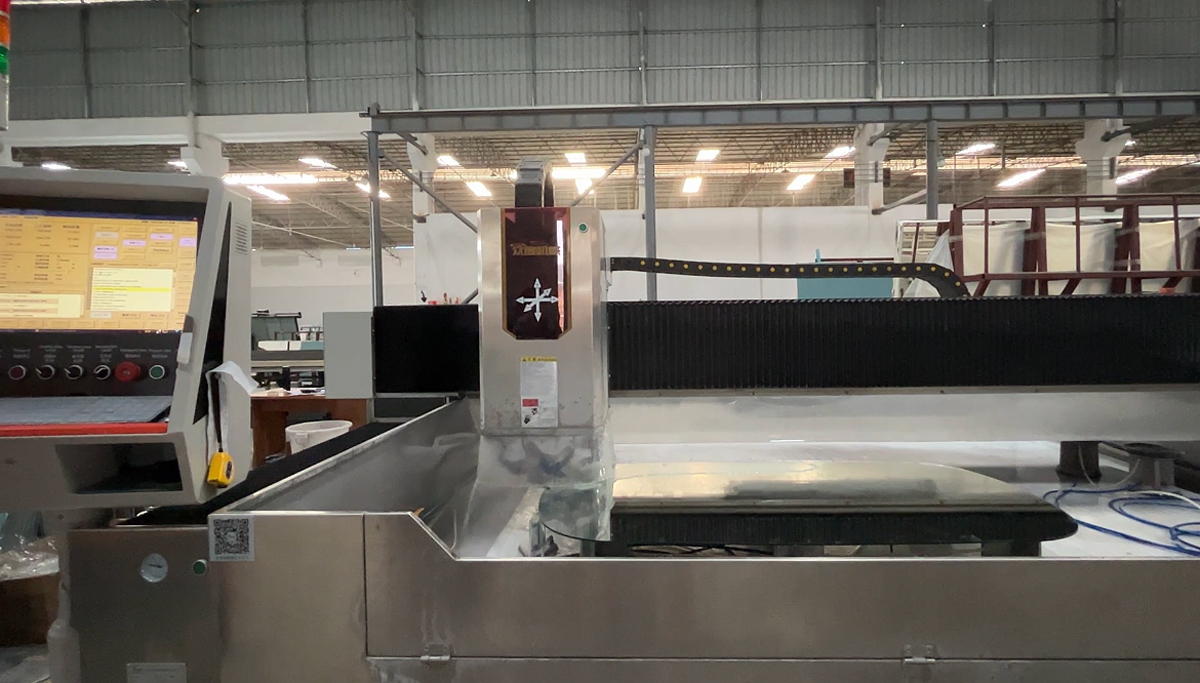

We have a wealth of mechanical automation equipment, as well as a high production capacity, advanced technological level and comprehensive economic strength, placing us at the forefront of the domestic industry, intelligent automation equipment, material control, equipment performance, and modeling has been in the country, encompassing a number of techniques. Have filled the domestic blank. The good after-sales service and reasonable prices have earned long-term customer praise. In line with the principle of "good faith first, customer satisfaction", our company has established long-term cooperative relations with many enterprises.

FAQ:

1. What is a glass laser cutting machine, and how does it work?

A glass laser cutting machine is a tool used to cut or engrave glass materials using a focused laser from an from infrared picosecond laser source. The laser beam heats the glass surface, causing it to melt, vaporize, or break, and creating precise cuts or designs.

2. Which types of glass can be cut using a laser cutting machine?

Glass laser cutting are capable of cutting cut various types of such as including float glass, tempered glass, laminated glass, stained glass, and more. The type and thickness of the glass can influence the cutting parameters.

3. What are the advantages of using a glass laser cutting machine compared to traditional cutting methods?

Laser offers provides high precision and intricate cuts on glass materials, which difficult challenging to achieve with traditional methods. It also allows for automation, reducing the need for manual labor and increasing efficiency.

4. Can a glass laser cutting machine engrave designs on glass surfaces? What about the working size?

Yes, glass laser cutting machines can not only cut glass but also engrave intricate designs, patterns, and textures on glass surfaces. The working area is 600*700mm and features a double-station cutting workbench. We also offer customization options for sizes such as 1000x2500mm and 1500x3000mm, among others.

5. What safety precautions should be observed when operating a glass laser cutting machine?

Safety measures include suitable appropriate personal protective equipment (PPE), adequate proper ventilation in the workspace, adhering to following the manufacturer's guidelines and safety protocols.

6. What factors should be considered when selecting a glass laser cutting machine?

Factors to consider include laser power, cutting area size, dimensions, size, cooling system, software compatibility, the specific the type of glass materials you will be working with.

7. How to maintain a glass laser cutting machine for optimal performance?

Regular maintenance, such as cleaning the lens, calibrating the machine, and checking for any mechanical issues, is essential to ensure the machine operates at its best.

8. Is specialized training required to operate a glass laser cutting machine?

Yes, operators should adequate proper training on to safely and efficiently to use machine, efficiently, as well understand understanding the software and settings various different glass-cutting applications.